Maintaining electrical safety in aquatic and leisure environments is a non-negotiable obligation for every facility operator. One of the most critical components of your compliance and risk management strategy is test & tag—the process of inspecting and testing electrical equipment to ensure safety under AS/NZS 3760:2010.

At Rest Assurance, we specialise in test & tag services for aquatic centres, gyms, pools, and leisure facilities throughout Melbourne, Victoria, and Adelaide. This comprehensive guide will help you understand what test & tag involves, why it matters, how often it’s required, and how Rest Assurance helps you stay compliant and safe.

What Is Test & Tag?

Test & tag refers to the process of inspecting and testing electrical appliances and equipment for safety, followed by tagging each item to indicate its compliance status. This process involves:

- Visual Inspection: Checking for signs of wear, damage, and non-compliance.

- Electrical Testing: Using calibrated instruments to measure key parameters.

- Outcome Assessment: Determining whether the item passes or fails.

- Tagging: Labelling the equipment with the results and retest date.

- Record Keeping: Logging all test results for compliance and audit purposes.

All of this is performed in accordance with AS/NZS 3760:2010, the Australian standard for in-service safety inspection and testing of electrical equipment.

Why Test & Tag Is Critical in Aquatic and Leisure Facilities

Environments such as aquatic centres, gyms, and public pools are inherently high-risk for electrical incidents due to:

- Moisture and Humidity: Water increases the risk of electrical short circuits and corrosion.

- High Usage Equipment: Appliances and machinery are used frequently and heavily.

- Public Exposure: Faulty equipment could result in injury or worse, impacting your reputation and legal standing.

Failing to comply with test & tag requirements can result in:

- Legal Penalties for breaches of Work Health and Safety (WHS) regulations

- Insurance Denials in the event of incidents

- Operational Shutdowns following safety audits

By engaging Rest Assurance’s test & tag services, you safeguard your visitors, protect your staff, and maintain a strong safety record.

What Does the Test & Tag Process Include?

At Rest Assurance, we go beyond basic checks to deliver comprehensive test & tag services:

1. Detailed Visual Inspection

Every item is carefully inspected for:

- Frayed or damaged cords

- Cracked plugs or exposed wires

- Signs of overheating or corrosion

- Incorrect voltage or wiring modifications

- Damaged casing or enclosures

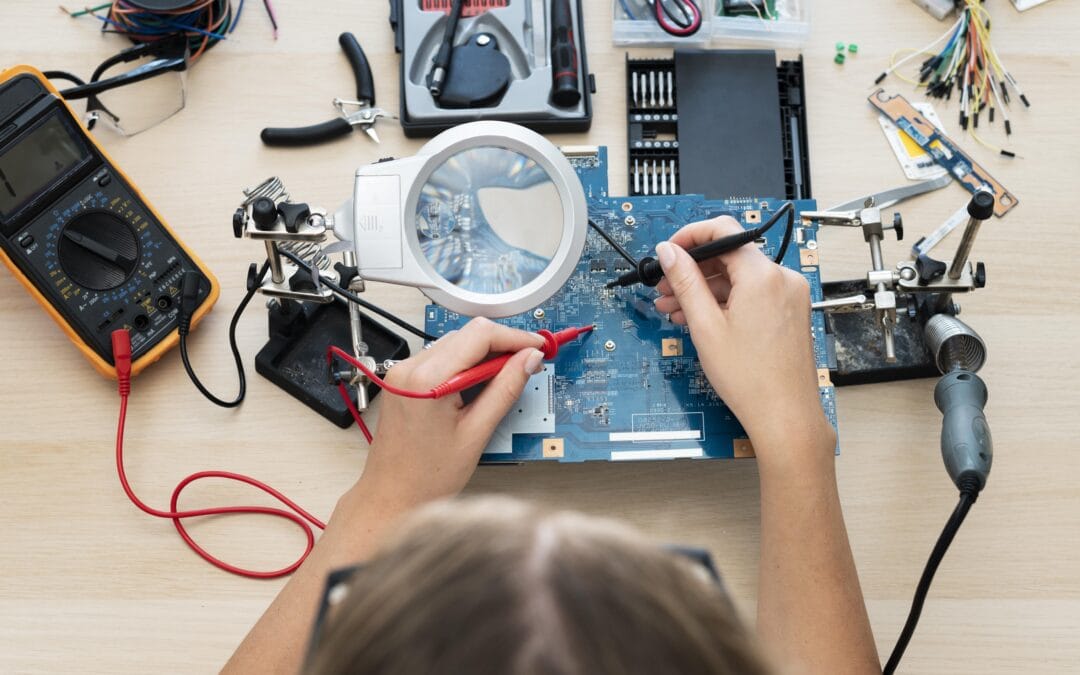

2. Electrical Testing Using Instruments

We use state-of-the-art, calibrated equipment to conduct:

- Insulation Resistance Testing – Ensures the device is properly insulated.

- Earth Resistance Testing – Validates that the earthing path is effective.

- Leakage Current Testing – Checks for current escaping to earth.

- Polarity Testing – Confirms that wiring is correctly connected.

3. Outcome Assessment & Tagging

Each item is marked with a tag showing:

- Test date

- Result (PASS or FAIL)

- Technician ID

- Retest due date

4. Compliance Reporting

You receive a full report with:

- Asset register

- Test results

- Retest schedule

- Maintenance recommendations

How Often Should You Test & Tag?

The frequency of test & tag depends on the environment and equipment type, as specified in AS/NZS 3760:

| Environment | Test Interval |

|---|---|

| Wet areas (e.g., aquatic centres) | Every 6 months |

| Construction sites | Every 3 months |

| Offices, schools | Every 12–24 months |

| Workshops and maintenance areas | Every 6–12 months |

Note: Equipment failure, damage, or relocation can also trigger the need for immediate re-testing.

Who Is Responsible for Compliance?

Under WHS laws, the Person Conducting a Business or Undertaking (PCBU) is responsible for ensuring equipment safety. This includes:

- Facility managers

- Safety officers

- Maintenance leads

Neglecting test & tag obligations could result in personal liability, especially in the event of injury or property damage.

Test & Tag vs. Other Safety Services

While test & tag ensures portable appliance safety, comprehensive compliance also includes:

- RCD Testing: Protects against electrocution by monitoring power imbalances.

- Exit Light Testing: Required under AS/NZS 2293 to ensure emergency lighting functions during blackouts.

- Thermal Imaging: Detects faults in switchboards and circuits before they fail.

- Microwave Testing: Assesses commercial kitchen appliance emissions.

- Three Phase Testing: For industrial equipment requiring high voltage.

Bundling services with Rest Assurance guarantees full-spectrum electrical safety.

Why Rest Assurance?

Here’s why aquatic and leisure facilities across Melbourne and Adelaide trust us:

- Specialists in High-Risk Environments: We understand the unique compliance needs of pools, gyms, and wet areas.

- Qualified Technicians: All services performed by certified professionals with AS/NZS 3760 training.

- Cutting-Edge Equipment: Ensures accurate readings and fast service.

- Custom Scheduling: Minimise disruption to your facility’s operations.

- Audit-Ready Reporting: Full documentation to support WHS compliance and insurance.

Thermal Imaging + Test & Tag = Maximum Safety

Combining thermal imaging with test & tag services gives you unparalleled visibility into your electrical infrastructure. Thermal scans detect heat anomalies in fixed installations—something test & tag alone can’t do.

This combination is especially powerful in:

- Equipment rooms

- Plant rooms

- Switchboards and DBs

Documentation and Compliance Logbooks

All test & tag activities must be documented in a logbook that includes:

- Date of inspection

- Asset identification

- Results of the test

- Name and licence of technician

- Tag expiry date

Rest Assurance provides digital and physical documentation that can be presented during WHS inspections or insurance audits.

FAQs About Test & Tag

Q: Is testing and tagging mandatory in Victoria and South Australia?

A: Yes. WHS regulations across all states require compliance with AS/NZS 3760 for all workplaces using electrical equipment.

Q: What happens if I don’t test my equipment?

A: You risk serious consequences including legal fines, loss of insurance cover, or injuries leading to liability claims.

Q: Can I test and tag equipment myself?

A: Only if you are a competent person—trained and equipped in accordance with AS/NZS 3760. In most cases, a licensed professional is required.

Q: How long does it take to test and tag?

A: Most jobs are completed within a few hours, depending on the number of assets. We schedule visits to suit your operating hours.

Real-World Example: Leisure Centre Compliance Audit

A large aquatic centre in Adelaide engaged Rest Assurance to conduct a full test & tag audit. During the inspection, our team identified several high-use appliances with insulation resistance issues. The faulty equipment was immediately removed from service, replaced, and documented.

During a subsequent government safety audit, the centre presented our compliance reports, avoiding penalties and earning commendation for proactive safety practices.

Test & Tag and Insurance Risk Management

Insurers often require proof of regular test & tag services to:

- Validate claims following an incident

- Assess premium eligibility

- Confirm due diligence on safety

Rest Assurance provides detailed, timestamped records and photographic evidence to support your insurance requirements.

How to Prepare for Your Test & Tag Appointment

Before our team arrives, ensure:

- Easy access to all electrical equipment

- Items are disconnected and ready (if possible)

- Staff are informed of temporary disruptions

We’ll handle the rest—discreet, professional, and fast.

Conclusion: Stay Compliant and Safe with Rest Assurance Test & Tag Services

Test & tag is not just about ticking a compliance box—it’s about protecting your staff, your patrons, your reputation, and your bottom line. For aquatic and leisure facilities where risk is amplified by moisture, usage, and public exposure, expert electrical safety testing is essential.

Get in touch with Rest Assurance today for a free quote or to schedule your facility’s next test & tag inspection.

Phone: +61 1300 801 596 | Email: info@restassurance.com.au

Proudly serving facilities across Melbourne, Victoria, and Adelaide with reliable, standards-aligned safety testing.

Let me know if you’d like a Part 2 follow-up guide, such as “How to Interpret Your Test & Tag Report” or a version tailored for schools, offices, or industrial settings!